Process Capabilities

Roll Forming / Structure

EnerG Linkage into the contract manufacturing with our renowned strategic partners of different types and sizes of Structure parts like Beam, Tubes, Angle, I – Section and C- Channels as per International Standards.

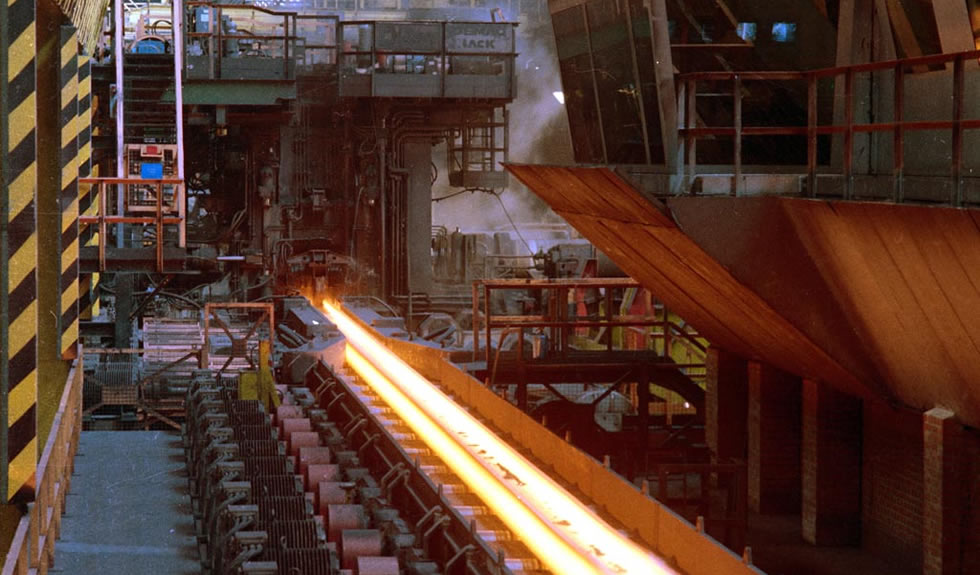

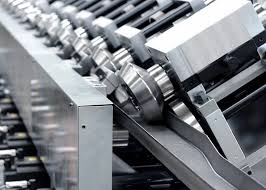

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

Mild Steel is the most used raw material for roll forming but ductile iron can also be used. Raw material can be used in two forms either Galvanized or Black. EnerG Linkage can supply Tubes in different profile like Rectangle, Square, Round and any other customized shapes in different material grades.

Beam

- W6 & W8 series beam.

- Solar Beam cutting, punching.

- Welding & HDG with high quality.

- Beam Material ASTM A572 Grade 50 or ASTM A992 Grade 50 / 60 /& 80 KSI YS.

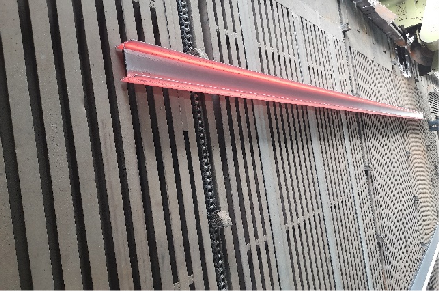

Tube

- Pre-galvanized Material for Torque Tube, structure Tube.

- Tube (Square, Circular and rectangular) for structure, Automobile & OEM.

- Welding & HDG with high quality.

- Tube Material as per ASTM A653 which cover all material grades.

Structure Shape

- I Section, Angles, C Channel as per all Indian & US Standard.

- Welding & HDG with high quality.